Products > Switch Controls & Signaling > Switch Point Slider

Stop the #1 Cause of

Train Delays

Switch Point Slider

#1 Cause of Train Delays

Switch failures are the #1 cause of train delays on all railroads. Approximately 90% of these failures are due to the switch point circuit controller indicating that the switch point is “out of correspondence” or “gapped”.

Proven Technology Saves Millions of Dollars

We have installed the switch point slider in the field with select Class 1 railroads achieving significant results and savings. Prior to installing the switch point slider, switches in harsh environments–scorching hot summers, freezing winters–frequently failed due to loss of correspondence and requiring expensive and time-consuming manual re-calibration. After installing the switch point slider, these same switches have not required any re-calibration for more than two years.

Problem: Out of Correspondence

Another contributing factor to the switch failures is the switch rods or basket becoming lodged on the ties when the basket is jammed against it from the expansion and contraction of the points. This results in damaged ties, insulation and spring/center baskets.

In the most serious cases, running rail damages the internal switch machine components due to the excessive force required to throw the switch machine.

Harsh Environments

Lead to Running Rail

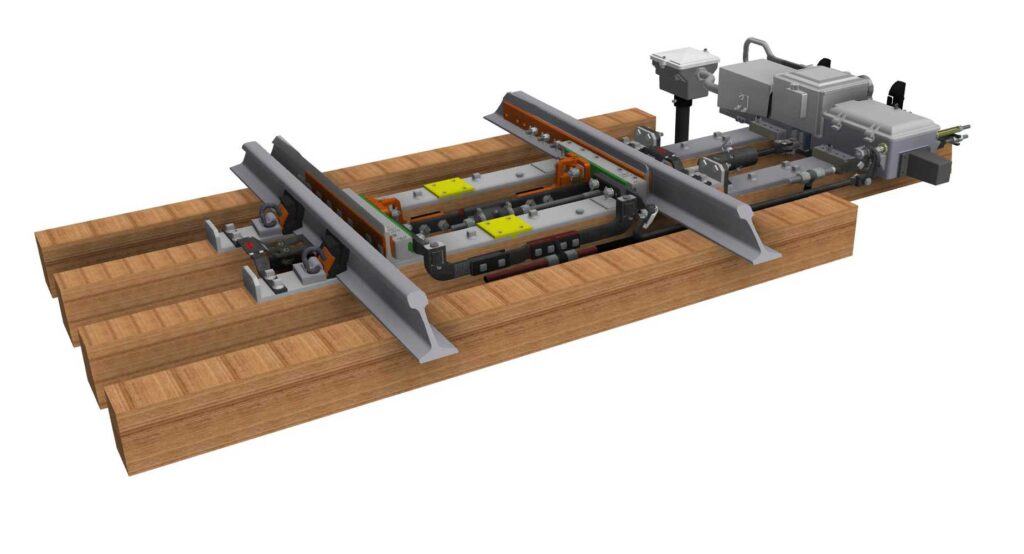

Solution: Switch Point Slider

Our patented Switch Point Slider system addresses the one of the primary causes of train delays. Ambient air temperature changes cause expansion and contraction of mainline switch rail points.

The expansion and contraction of the rail points change the geometry of the switch layout resulting in the switch being unable to correctly detect the position of the points. This results in stoppage of trains as well as requires a maintenance crew to go out and re-adjust the switch so that it properly detects the rail points.

The Switch Point Slider system actually allows the points to move freely and independently while maintaining perfect geometry of the rods to the switch machine. The counter beveled sliders compensate for the taper of the switch point as it moves, thus eliminating inward and outward movement of the point detection and operating rods.